What role does CNC PU dispensing machine play in the sealing industry?

What is CNC PU foam sealing gasket machine?The CNC PU foam sealing gasket machine is a special control fluid, drip, coating,sealing liquid on the surface of the product or inside the automatic machine.CNC PU foam sealing gasket machine is mainly used for glue, oil, paint and other liquids in the product process. Note that the precise position of the coating, drop to each product, can be used to achieve points, lines, circles or arcs.

Advantages of CNC PU foam sealing gasket machine

The foam sealing strip made by the CNC PU foam sealing gasket machine has good waterproof and dustproof effect, and is suitable for various application scenarios such as surface sealing and internal sealing and gluing. The whole set of CNC PU foam sealing gasket machine production equipment technology is stable, no plug does not die, long service life, stable operation is guaranteed.

Application of CNC PU foam sealing gasket machine

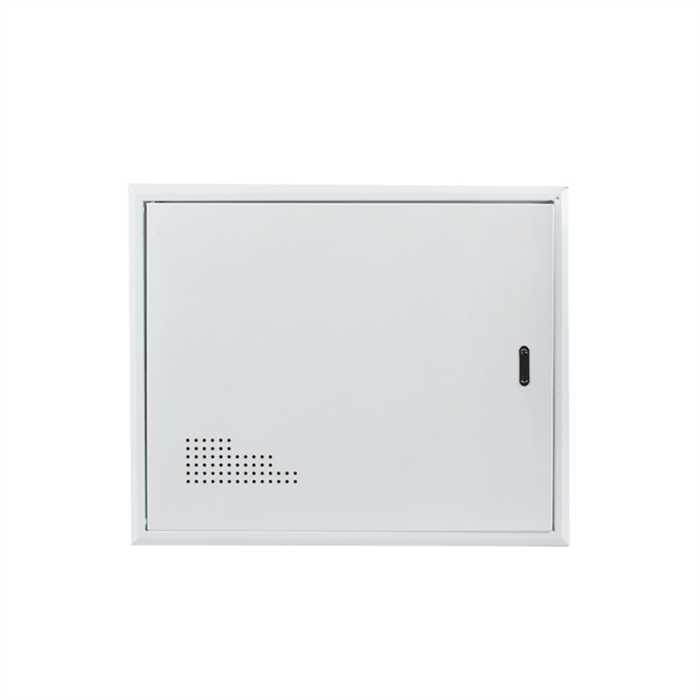

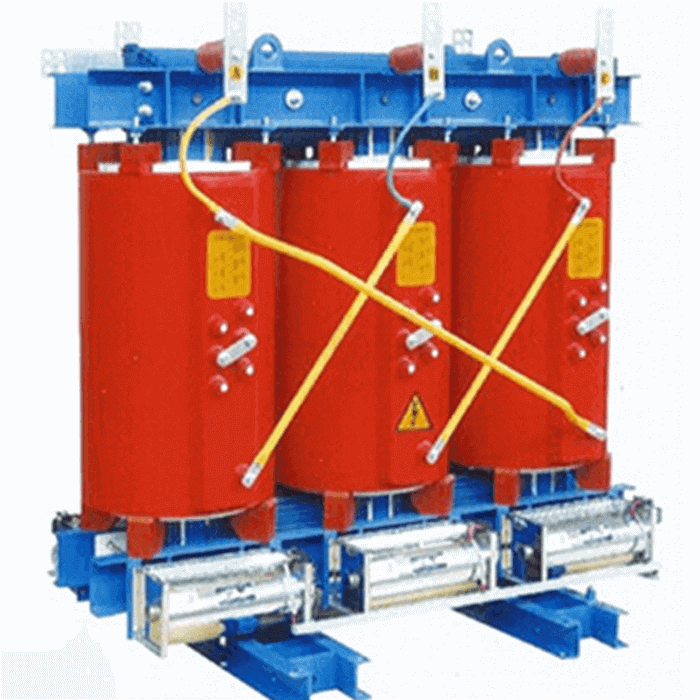

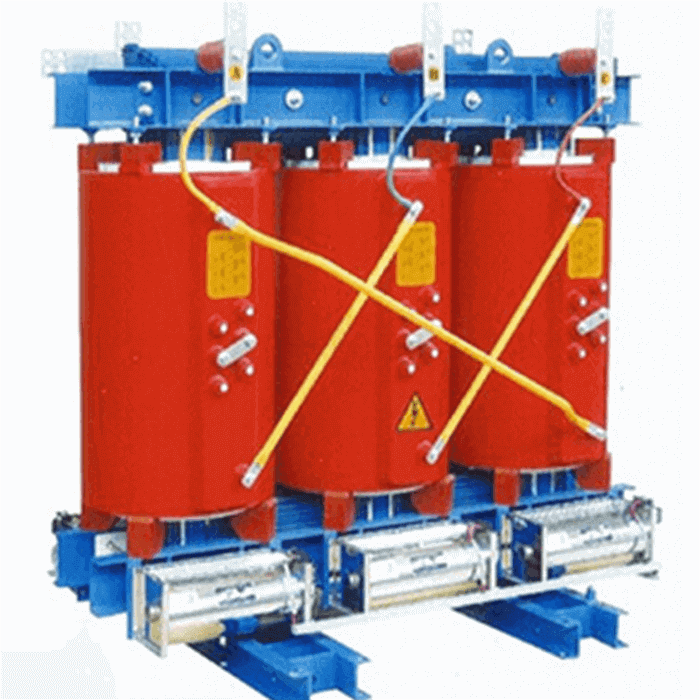

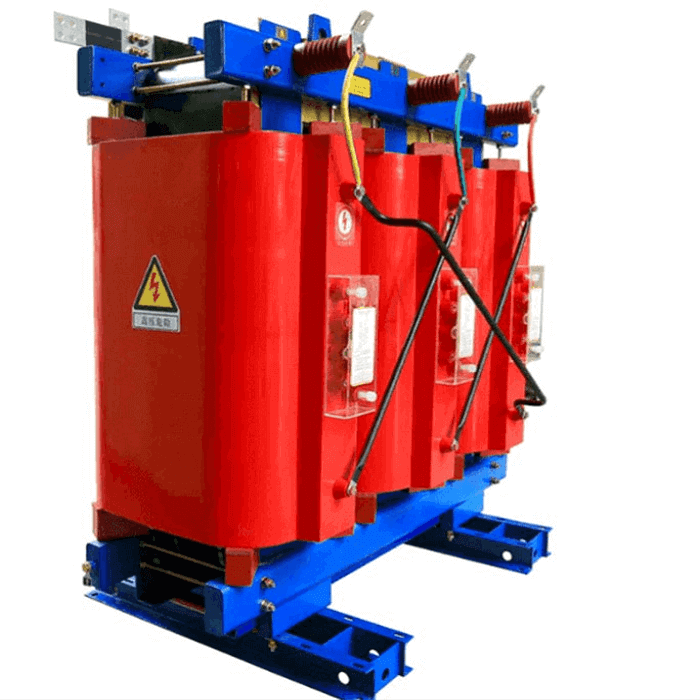

At the moment,CNC PU foam sealing gasket machine has been widely used in distribution cabinet door, distribution box door, control cabinet door, chassis cabinet door, imitation weitu cabinet door, base box, power box, stainless steel distribution cabinet,switch cabinet,JP cabinet, GGD, sheet metal shell processing, air purification filter, purification door, clean workshop door, waterproof box,explosion-proof electrical appliances, explosion-proof lamps,household appliances,Marine electrical Equipment,vacuum cleaners,sweeping robots,new energy electric vehicle charging pile shell,radiator,outdoor LED lamps, lighting lamps, signal lamps,auto parts,motorcycle parts,electric car parts,lithium battery boxes and other industries of sealing waterproof and dust.

What are the intelligent control functions of CNC PU foam sealing gasket machine?

3D teaching function:

By moving the parameters of the glue machine head, such as positioning length, width and height, turning, etc., three-dimensional product accurate dispensing can be achieved without drawing and importing the system, making the dispensing operation simple and easy to get started.

Matrix dispensing function:

Through the accurate positioning of the system, multiple small products can be dispense at the same time, such as base boxes, waterproof boxes, radiators, fans and other products, greatly improving the production efficiency.

Automatic alarm function:

Through the intelligent monitoring of the sensor, the automatic alarm sound will be issued when the shortage of materials, no air, collision, etc., to protect the safe use of the machine.

Automatic temperature control function:

By automatically adjusting the temperature and stirring of the barrel, the system does not need to install air conditioning, improves production efficiency, and eliminates the blockage of pipes and glue heads caused by temperature control problems.

Remote inspection function:

It can remotely inspect the operating status and failure of the equipment through WiFi, greatly improving the maintenance efficiency of the equipment,and can also remotely transmit parameters through WiFi, reducing the difficulty of operation of complex three-dimensional products.

Data memory function:

The historical dispensing data can be archived as a file package, and the next time the data package can be dispensed, reducing the loss caused by personnel flow.

Automatic cleaning function:

Through high pressure water cleaning, high pressure air drying dispenser pipe and the residual raw materials in the head, to achieve the head is not blocked, no leakage effect.

Automatic statistics function:

Real-time recording of glue length, time and dosage data, convenient cost accounting, production efficiency accounting, etc.

Long standby function:

Suitable for holidays, production adjustment and other time periods when the machine is not used for a long time, it can still be turned on and used after a long time of shutdown.

The Price of CNC PU foam sealing gasket machine

The price of CNC PU foam sealing gasket machine is subject to fluctuations of many factors, usually the price will be affected by raw materials, market environment, research and development costs, so there will often be different prices, if you want to know the latest price can contact me.

Supplier of CNC PU foam sealing gasket machine

Many companies in the field of CNC PU foam sealing gasket machine production are doing well, such as SHZ Power is a professional CNC PU foam sealing gasket machine manufacturer in China, if you want to know more about the latest product information of CNC PU foam sealing gasket machine, and want to find high-quality CNC PU foam sealing gasket machine, Please email us for the latest product quote and contact us.

The packaging technology of automatic dispensing machine has been used in electronic equipment products as early as a few years ago, but at that time, because of the huge and expensive overall equipment, only a few large and medium-sized enterprises have been used in production and manufacturing. As everyone knows, in recent years, with the rapid development of the field of automatic dispensing machine, its cost performance has also made a very large improvement, which makes many small and medium-sized enterprises can also use automatic dispensing machine to promote the production line of their products, and then provide better economic benefits to the company.

In addition, the control of the amount of glue is very critical to the gluing process of the automatic dispensing machine, because of the high integration of the gluing product, the fraction deviation of the amount of glue will directly affect the quality of the gluing. The amount of glue will lead to waste and obstruction, on the contrary, it will not be the effect of glue packaging, so choose a good automatic dispensing machine suitable for the production of their own products is very key to the development of the company. Here, I seriously recommend CNC PU foam sealing gasket machine glue, machine automatic ratio, automatic gluing, quantitative gluing, automatic path, one-key cleaning, saving time and effort.