What are the advantages of CNC PU foam sealing gasket machine?

What is CNC PU foam sealing gasket machine?

CNC PU foam sealing gasket machine is a professional control fluid, drip, coating, sealing liquid on the surface of the product or inside the automatic machine. CNC PU foam sealing gasket machine is mainly used for precision point, filling, gluing, coating and other liquids in the product process, drip irrigation to every precise position of the product, can achieve point, line, circle or arc.

CNC PU foam sealing gasket machine application range

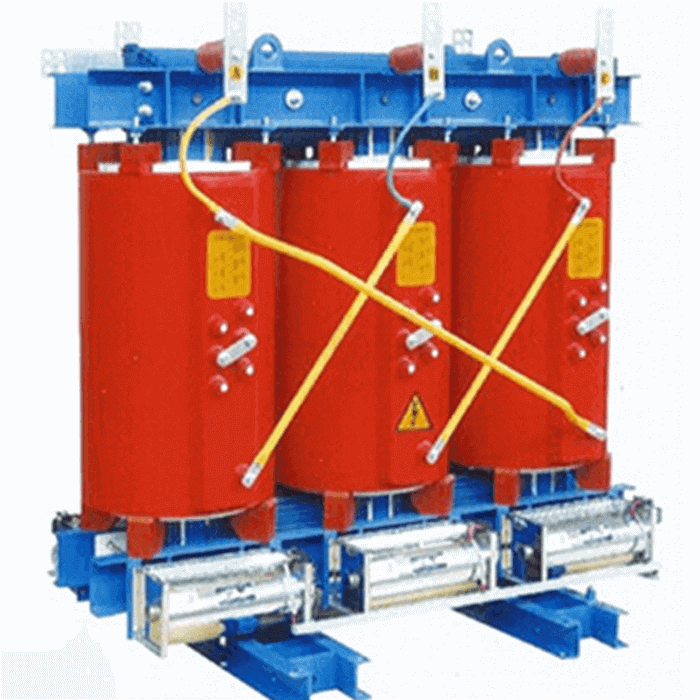

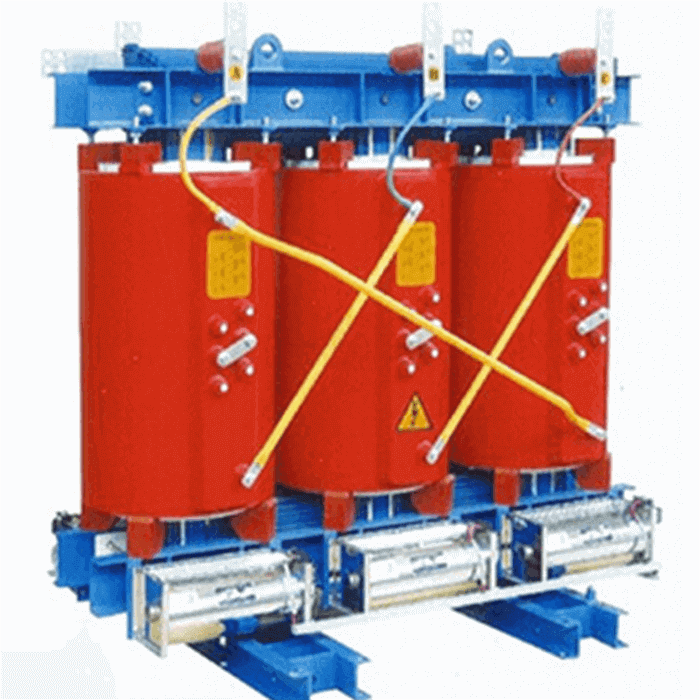

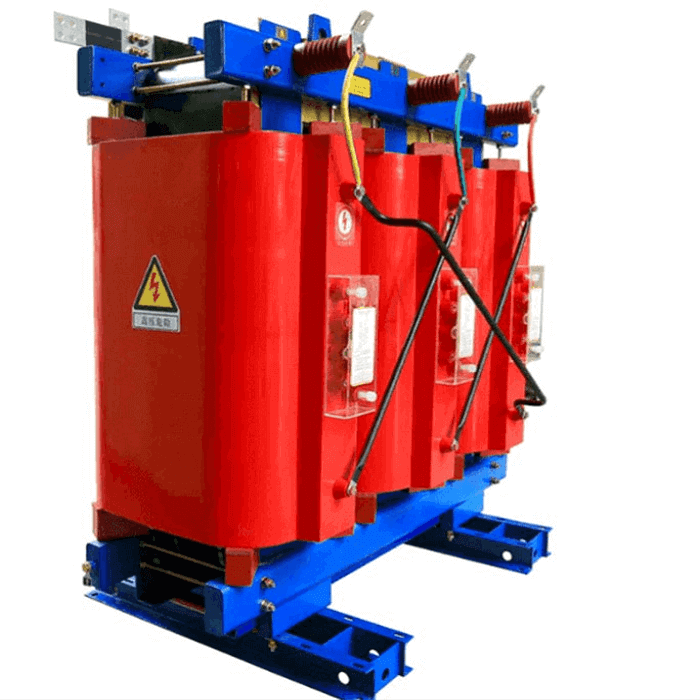

CNC PU foam sealing gasket machine is suitable for various fields of industrial production, including national defense, mechanical construction industry, medical electronic and electrical industry, lighting equipment, electronic components and other fields. Specifically applicable to cabinets, explosion-proof products, waterproof water tanks, door locks, automobiles, household appliances, frequency converters, integrated circuits, circuit boards, liquid crystal screens, relays, speakers, crystal components, LED lights, shell bonding, optical lenses, mechanical parts sealing, etc.

Advantages of CNC PU foam sealing gasket machine

1.Accurate measurement

The ratio is high, which can ensure the uniform foaming of PU foam sealing strip, and the mixing ratio of A and B glue is consistent during the whole pouring process. At the same time, the spitting accuracy is high, to ensure that the total amount of spitting per unit time is consistent, and to prevent the change of the volume or thickness of the seal strip from causing defective products or waste products.

2.Mix well

After the two-component sealing gasket foam is mixed evenly in the pouring head, it is poured into a qualified polyurethane PU foam sealing gasket to ensure that the physical properties of the entire sealing gasket are consistent (when cutting the sealing strip, the bubble holes of its section should be uniform).

3.Constant temperature control

The temperature of the raw material directly affects the fluidity and reaction speed of the glue, so ensuring that the temperature of the raw material is stable and not affected by the external environment is a necessary condition for the normal production of PU foam seals and to ensure its yield.

4.Accurate alignment

According to the size and thickness requirements of the pouring filter, quantitative and constant speed pouring is carried out by controlling the lateral, longitudinal and circular movement of the pouring head, so that its size, shape, thickness and physicality can meet the requirements.

5.Good sealing effect

There is no joint gap after the glue curing, and the sealing effect and comprehensive performance are higher than the EPDM rubber gasket commonly used in China.

6.High process efficiency

Automatic PU sealing gasket machine directly on the surface of the product dispensing, do not need to spend a lot of labor and time to paste, both efficient and accurate, the use of high efficiency filter only about 1 minute, you can perfect the production of automatic sealing gasket. The sealant is fully cured in a short time after foaming and goes into the next process to increase productivity and ensure that the tightness passes the test once.

What are the precautions for CNC PU foam gasket machine operation?

1.When the machine is shut down for a long time, it must be buttered at the thread to prevent the glue from drying and air intake.

2.After each change of glue nozzle, do not open the glue gun to go through a process, observe whether aluminum touches the muzzle during the process, if so, immediately report to the technician.

3.Operators are not allowed to adjust system parameters without authorization.

4.Do not physically invade the work area during operation.

The price of CNC PU foam sealing gasket machine

The price of CNC PU foam sealing gasket machine is subject to fluctuations of many factors, usually the price will be affected by raw materials, market environment, research and development costs, so there will often be different prices, if you want to know the latest price can contact me.

CNC PU foam sealing gasket machine supplier

With the rapid development of CNC PU foam sealing gasket machine production field, CNC PU foam sealing dispensing machine cost performance has also made a very large improvement, which makes many small and medium-sized enterprises can also use CNC PU foam sealing dispensing machine to promote the production line, and then provide better economic benefits for the company. Choosing a good CNC PU foam sealing dispensing machine suitable for the production of their own products is very key to the development of the company. Here, I seriously recommend SHZ Power, which is a professional manufacturer of CNC PU foam gasket machine in China, if you want to know more about the latest product information of CNC PU foam gasket machine, and want to find high-quality CNC PU foam gasket machine, welcome to send an email to get the latest product quotation and contact us.