The introduction to the box type substation

What is a box type substation?

Box type substation, also known as a preinstalled substation. Is a kind of high voltage switch equipment, distribution transformers and low voltage power distribution equipment, according to the wiring scheme must be arranged in one of the factory indoor, outdoor compact type distribution equipment, the step-down transformer, low voltage power distribution, and other functions organically combined together, installed in moisture, rust, dust, rat, fire prevention, guard against theft, heat insulation, fully enclosed, movable steel box, Especially suitable for urban network construction and transformation, it is a new substation after the rise of the civil substation. The box-type substation is suitable for mines, factories, oil and gas fields and wind power stations. It replaces the original civil power distribution room and power distribution station and becomes a new complete set of transformer and distribution devices.

How does the box type substation work?

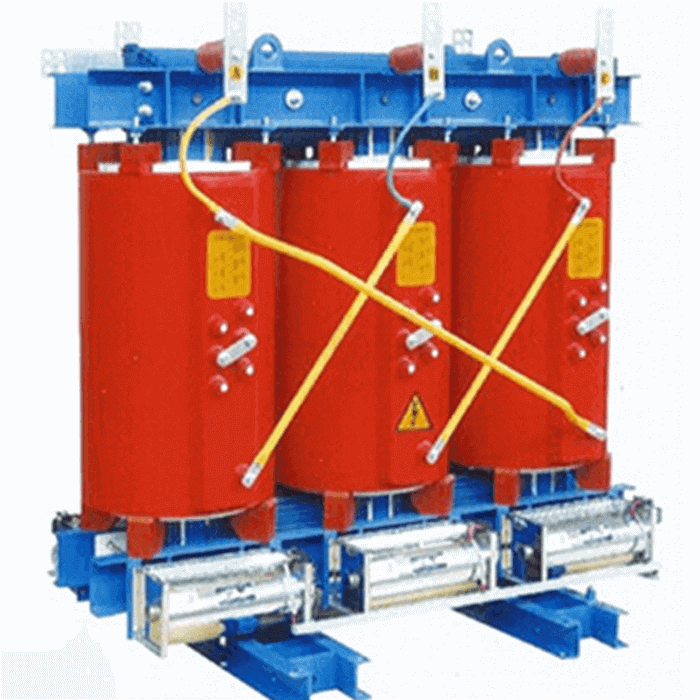

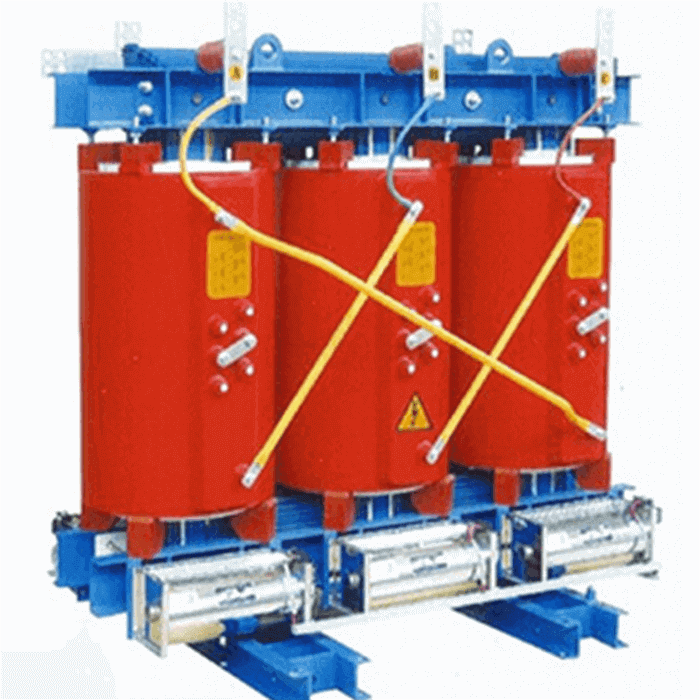

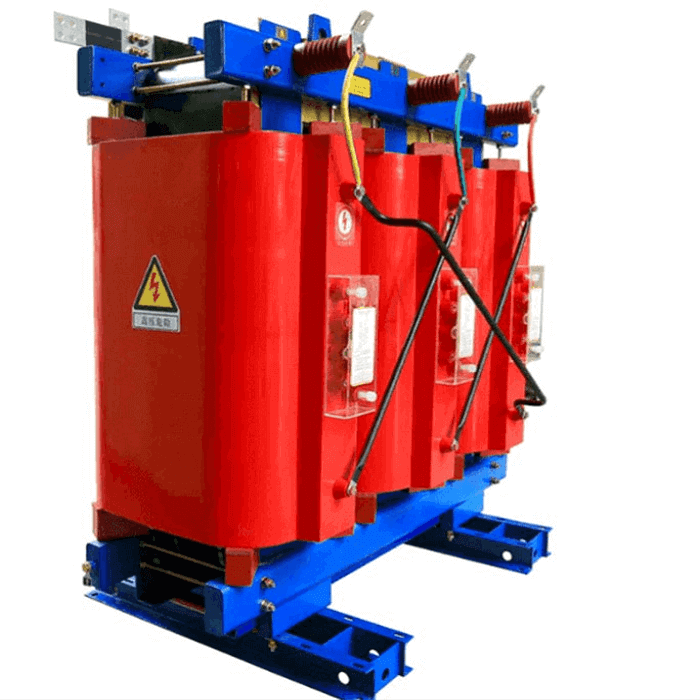

box type substation is a compact complete set of power distribution devices that combine high-voltage switchgear distribution transformers, low-voltage switchgear, electric energy metering equipment and reactive power compensation device in one or several boxes according to a certain wiring scheme. It is suitable for rated voltage 10/0.4kV three-phase AC system, as a line and power distribution.

Compared with the European box of the same capacity, the structure of the American box is more reasonable. Because the European box is the transformer and ordinary high-voltage electrical equipment is installed in the same metal shell box, transformer room temperature is very high, causing heat dissipation difficulties, and affecting output; On the other hand, ordinary high-voltage load switches and fuses and low-voltage switchgear are used in the box, so the European box is larger in variable volume. American box change and European box change structure is different. From the point of view of the layout, the low voltage chamber, transformer room, and high voltage chamber is not a font layout, but a product font layout. From the point of view of the structure, the box is divided into two parts before and after the front of the high and low-pressure operation interval, operation interval includes high and low-pressure wiring terminals, load switch operating handle, no-load regulator node switch, plug fuse, oil level meter, etc.; At the rear are the filling tank and heat sink, and the transformer windings, iron cores, high-voltage load switches and fuses are put into the transformer tank.

Precautions for installation and operation of box-type substation

The shell door of the box substation should open outwards, and there should be handles, dark latches and locks, which should be rust-proof. The transformer room should be given priority to natural ventilation, and the relationship between temperature in the box and transformer output is given. A room temperature monitoring device and self-starting ventilation cooling device can be installed in the transformer room according to the need to ensure that the transformer runs at full load under specified environmental conditions. The transformer shall be accessible from the top or side door of the box. The noise level of the box substation shall not be greater than the specified transformer noise level. Whether metal or non-metal materials are used in the case shell, the metal frame of the case should be well grounded, with grounding terminals, and marked with grounding symbols.

The box-type substation is mainly cooled by natural air circulation. Therefore, there should be no illegal pile around it, especially the transformer room door should not be blocked, but also often remove the attachment on the shutter vent hole, to ensure that all electrical equipment does not exceed the maximum allowable temperature. Low-voltage circuit breaker trip should check the trip cause before trial. If the fault is not successfully sent, it is necessary to thoroughly find the cause of the fault and eliminate it before sending power to prevent the expansion of the accident. Zinc oxide arrester shall be installed in the high voltage distribution room of the box transformer in a manner convenient for test and disassembly and replacement.

The floor of the box-type substation should be placed in a higher place, not in a low-lying place, so as to avoid rainwater pouring into the box and affecting the operation of the equipment. When casting a concrete platform, there should be a gap at the high and low-pressure sides to facilitate the laying of cable inlet and outlet lines. When the foundation is excavated, if the ground is formed by the accumulation of garbage or potting soil, it is necessary to dig solid soil, and then backfill the better soil and tamp it, and then fill the mixture or slag to ensure the foundation is stable.

Leading One-stop Power Distribution and Electrical Automation Solutions Manufacturer

Shunzhi Power Electric Equipment Co., Ltd. (SHZPower) is a long-history high-tech enterprise dedicated to the scientific research, design and domestic and foreign trade of CNC glue dispensing machine, Multicolor Industrial Inkjet Printing Machine,electrical automation, medium and low voltage switch cabinets, box-type substations, power distribution cabinets, and multimedia boxes. Headquartered in Luoyang, a beautiful historical and cultural city in China, the factory covers an area of more than 15,000 square meters and employs more than 80 people, of which more than 40% are professional and technical personnel.