How to install the oil-immersed transformer

Definition of an oil-immersed transformer

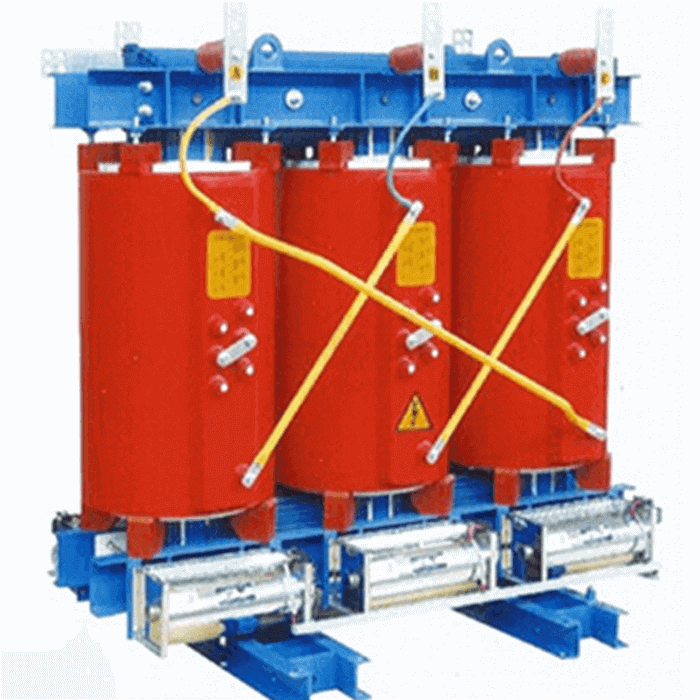

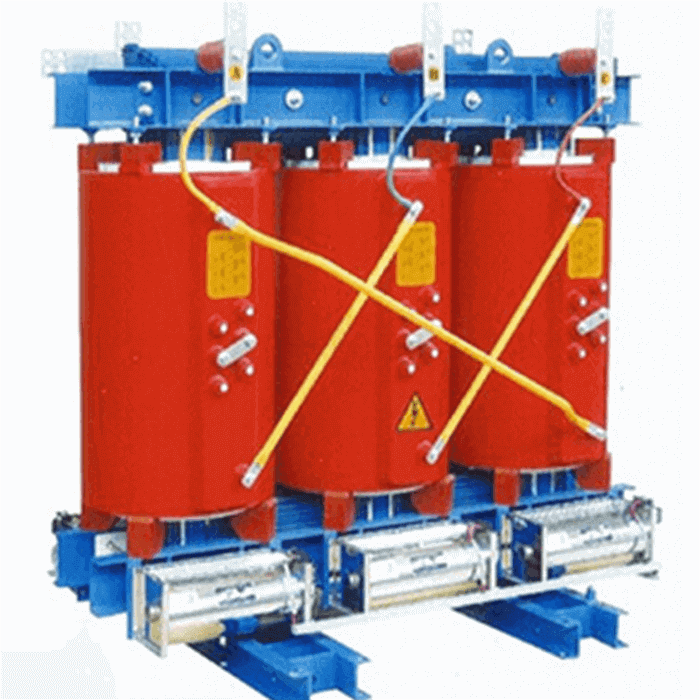

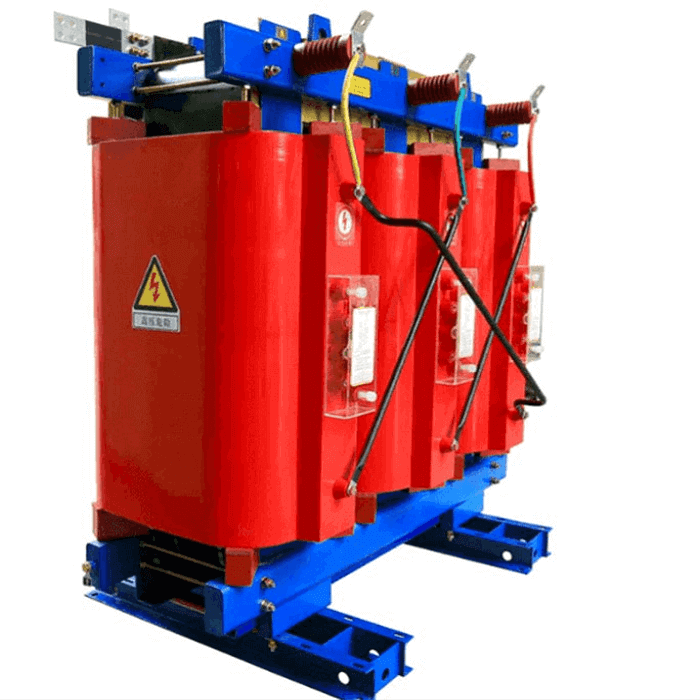

Oil-immersed transformer is a more reasonable structure, better performance of a new high-performance transformer, the three-dimensional core because of its three core is equal triangle stereo arrangement, no air gap, the winding closer, three magnetic road length, and the shortest, core column cross section area closer to the circle, so the performance is further improved, loss, noise reduction, three balance, reduce the three harmonic components, the product is more suitable for urban and rural, industrial and mining enterprise grid transformation, more suitable for combined transformer and pre-installed substation transformer.

Characteristics of an oil-immersed transformer

Oil-immersed transformer uses oil as the main insulation means of transformer, and relies on oil as the cooling medium, such as oil immersion self-cooling, oil immersion air cooling, oil immersed water cooling and forced oil circulation.The main components of the transformer are iron core, winding, oil tank, oil pillow, respirator, explosion-proof pipe (pressure release valve), radiator, insulation sleeve, tap switch, gas relay, thermometer, oil cleaner, etc.

Oil immersed transformer silicon steel sheet layer, because the oil can be immersed in the transformer for a long time, the oil can penetrate into it, and the transformer oil has an elastic buffer role, so the oil immersed transformer noise is small.But its voltage control switch in the fuel tank, the switch contact is not invisible outside, if the contact is not equal to the open circuit, such as bad contact, when the load is too large, easy to burn the switch.

How to install the oil-immersed transformer

Distribution transformer is an important component of the substation, and the oil-immersed transformer is generally installed in a separate transformer room.

Relying on oil as cooling medium, such as oil self-cooling, oil air cooling, oil water cooling and forced oil circulation.Generally, the main transformer of the booster station is oil-immersed, with the transformer ratio of 20KV / 500KV, or 20KV / 220KV. The general power plant transformer used to drive its own load (such as coal mill, induced draft fan, power supply fan, circulating water pump, etc.) is also an oil-immersed transformer, and its transformer ratio is 20KV / 6KV.

The oil-immersed transformer is of a fully oil-filled seal type.Ribligated oil tank housing with its own elasticity to adapt to the expansion of the oil is permanently sealed oil tank, oil immersion transformer has been widely used in the power distribution equipment.

1.Man hour quota: (according to the national quota standard) The comprehensive working day required for body installation is 21 working days.The work contents include: open box inspection, body positioning, device body inspection, casing, oil pillow and radiator cleaning, oil column experiment, attachment installation, cushion iron and wheel stop production and installation, supplementary column and overall sealing test after installation, grounding, paint filling, etc.Whether the transformer needs to be dried during installation shall be determined after inspection and judgment. The drying day with iron loss drying method is 20 days, and the working day required for oil filtration is 3.38 working day / ton.The work day required for commissioning shall be calculated separately.

2.Installation site layout: the overhaul and assembly of power transformer should best be carried out in the maintenance room.There is no maintenance room, it is necessary to choose a temporary installation place, it is best to choose near the foundation platform of the transformer, make the transformer in place, can also be installed on the foundation platform, outdoor site should be tents.Temporary installation places must be convenient for transportation, flat roads, with enough width, the ground should be solid, flat and dry, far away from the smoke Windows and water towers, and the distance from the nearby buildings to meet the fire prevention requirements.

3.Designated safety measures: ① to prevent personal electric shock and fall and other accidents.The ② prevents the insulation from overheating.③ prevents a fire.The ④ prevents something from falling into the fuel tank.⑤ prevents attachment damage.The ⑥ prevents the transformer from overturning.

4.Formulate technical measures: ① to prevent the transformer core from being damp.How does the ② ensure that each connection part is in good contact.All parts of ③ should be well sealed without oil leakage.④ How to ensure the transformer insulation and oil insulation.

5.Basic procedures for installation: ① preparation work (tools, materials, equipment, drawings) ② insulation inspection and judgment (mainly coil and core) ③ accessories inspection (should be complete, intact) ④ suspension core inspection (prevent moisture absorption and tools, parts, etc. Fall into the fuel tank) ⑤ accessories installation (appearance inspection, insulation measurement and tight line test) ⑥ ending work ⑦ handover test ⑧ trial run

6.Organization and division of staff: ① installation chief commander and technical director ② safety officer ③ oil filter group ④ lifting and transportation personnel ⑤ test personnel ⑥ installation personnel.

7.Requirements for transformer room: ① level 1 fire prevention ② good ventilation ③ safe distance should be enough ④ foundation platform should be reliable ⑤ lifting facilities should be in good condition.

8. Preparation:

⑴ Installation machine (e. g., vacuum pump, oil pump, oil tank, compressed air machine, oil filter machine, electric welding machine, running lamp transformer, valve, various wrench, etc.)

⑵ test instrument (such as shake meter, medium loss angle tester, booster transformer, voltage regulator, ammeter, voltmeter, power meter, thermometer, etc.)

⑶ crane tools (such as crane, hanger, crane beam, winch, wire rope, pulley, chain crane, etc.)

⑷ insulation materials (such as insulation oil, cardboard, cloth tape, electric board insulation paint, etc.)

⑸ sealing material (e. g. right rubber liner, asbestos rope, steel bottom, shellac paint, nylon rope, etc.)

⑹ bonding materials (such as epoxy resin glue, glue, cement, mortar, etc.)

⑺ cleaning materials (such as white cloth, alcohol, gasoline, etc.)

⑻ Other materials (such as asbestos board, square wood, wire, steel pipe, oil filter paper, petroleum forest oil, porcelain paint, etc.)

9. External inspection of the transformer: ①The content had no mechanical damage②The box cover bolts are intact③The liner is well sealed④ casing surface without defects⑤ without oil seepage and oil leakage phenomenon⑥ rust-free, paint-complete ⑦The accessories are left intact ⑧The roller wheel pitch coincides with the foundation track gauge in temperature.

Supplier of oil-immersed transformer

Leading One-stop Power Distribution and Electrical Automation Solutions Manufacture

shunzhi Power Electric Equipment CoLtd.SHZPoweris a long-history high-tech enterprise dedicated to the scientific research, design and domestic and foreign trade of CNC glue dispensing machine,Multicolor Industrial Inkjet Printing Machine,electrical automationmedium and low voltage switch cabinets, box-type substations, power distribution cabinets, and multimedia boxes.If you are looking for oil-immersed transformer or want to know more about us feel free to contact us.