How to accurately use Precision PU gasket dispensing machine

What is Precision PU gasket dispensing machine?

Precision PU gasket dispensing machine is a miniature precision sealing dispensing machine, which is a small micro-function dispensing equipment independently developed on the basis of the standard constant dispensing machine, mainly for the sealing dispensing of large and small workpieces. AB two-component polyurethane dynamic foaming machine head, through the Precision PU gasket dispensing machine glue polyurethane sealing rubber strip, with good waterproof and dustproof effect, suitable for product surface sealant, internal sealant and other application scenarios. The great advantage of this professional seal with an expandable PU gasket is that the seal can be applied directly and seamlessly to the product for optimal bonding. This virtually eliminates the risk of leakage.

Application field of Precision PU gasket dispensing machine

PU gaskets provide optimal protection against moisture, dust, vibration and various chemicals.

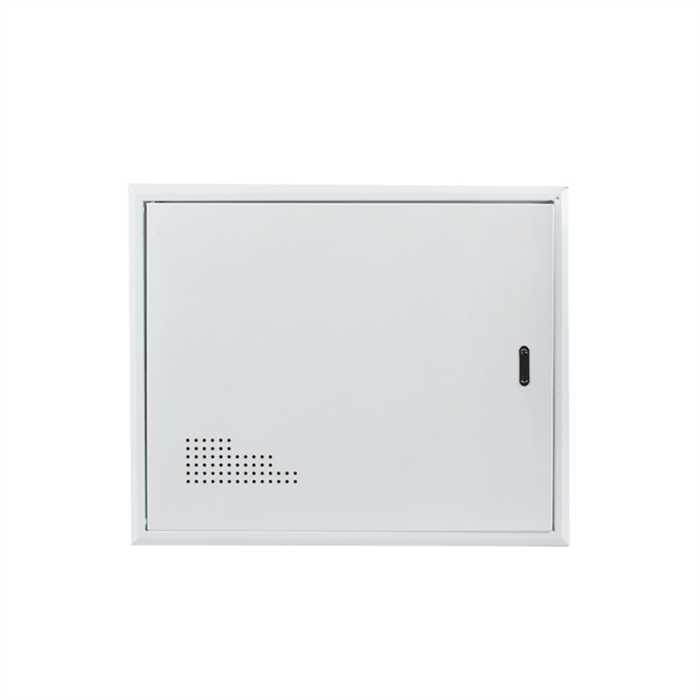

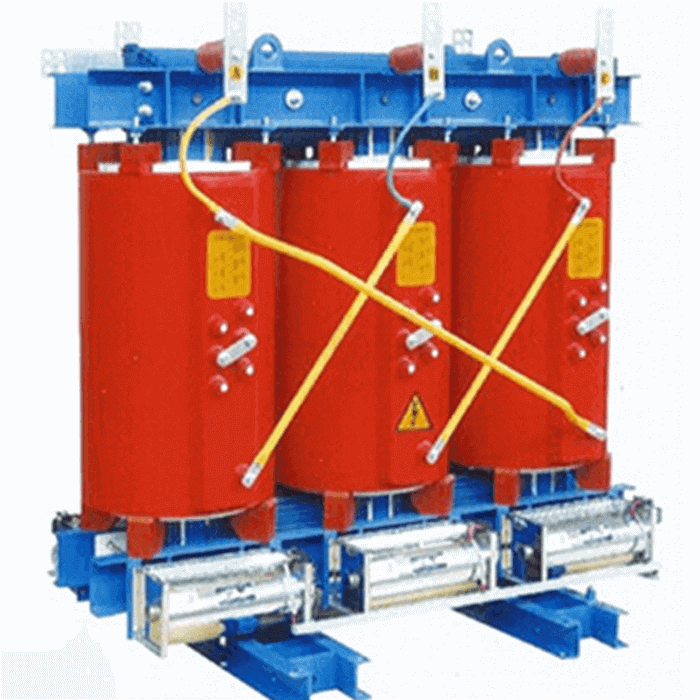

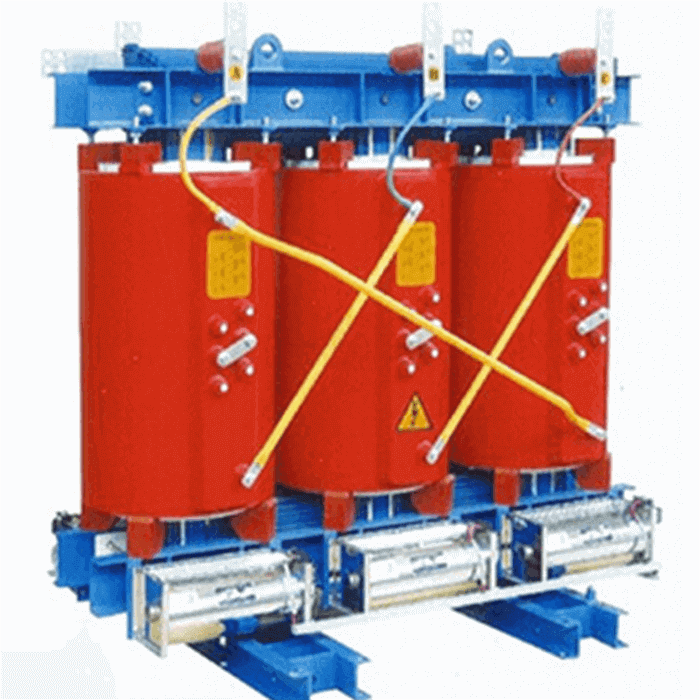

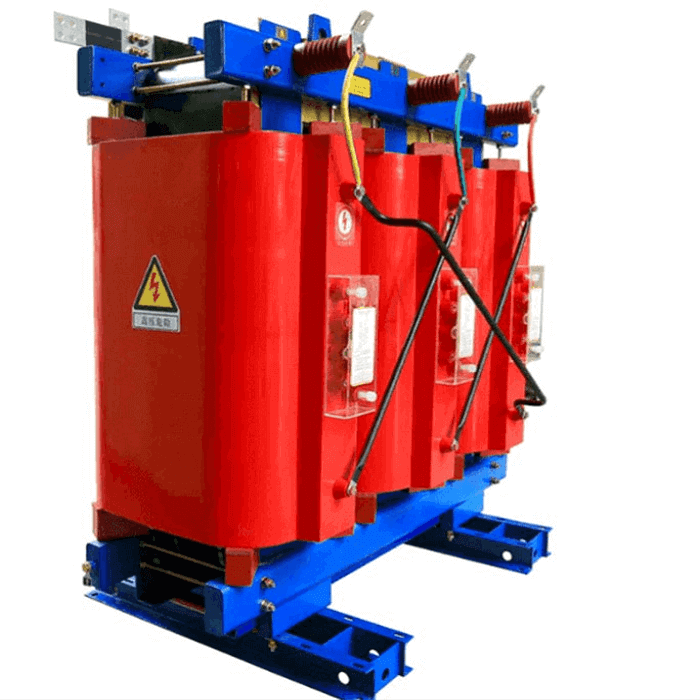

1.Seals for the control cabinet industry

2.Seals in electronic device housings

3.Seals around the ventilation grille

4.(HEPA) filter seal/connection

Characteristics of Precision PU gasket dispensing machine

1.High repeatability thanks to CNC controlled production technology

2.High IP protection rating (UL 50E) results in high quality standards

3.Rapid curing

4.Repeatability <0.15mm (ISO 9283)

5.On-line pretreatment and priming

Daily maintenance of Precision PU gasket dispensing machine

1.Cleaning and maintenance

Clean nozzles, pipes and mixers regularly to ensure smooth flow.

Remove blockages and residues to prevent buildup that could affect equipment performance.

Lubricate moving parts and bearings to reduce wear and friction and extend equipment life.

2.Check seals, 0-rings and pipe connections regularly to ensure tightness and prevent leaks

Check the working condition of pumps and filters, and clean or replace parts that need maintenance.

Replace damaged parts such as nozzles, hoses and mixers regularly.

3.Liquids and Materials Management

Ensure that liquid materials are stored in a proper environment, avoiding exposure to sunlight and high temperatures.

Regularly check the quality and expiration date of liquid materials, strictly comply with the use specifications.

Control the ratio and ratio of raw materials to ensure consistent foam quality and performance.

4.System performance and parameter adjustment

Check pressure sensors and flow meters regularly to ensure accuracy and stability.

Adjust spraying parameters and mixing ratio according to product requirements and process flow.

Calibrate temperature control system to maintain stable foam temperature.

The price of Precision PU gasket dispensing machine

The price of Precision PU gasket dispensing machine is subject to fluctuations of many factors, usually the price will be affected by raw materials, market environment, research and development costs, so there is no fixed price, if you want to know the latest price can contact me.

Supplier of Precision PU gasket dispensing machine

Many companies in the field of Precision PU gasket dispensing machine production are doing very well, such as SHZ Power is a professional manufacturer of Precision PU gasket dispensing machine in China, the company provides one-stop foam sealing equipment, color inkjet equipment, power distribution and electrical automation solutions. The company's full range of products have the characteristics of stable performance, energy saving and high efficiency, and through CQC certification, some products through the European CE certification. With many years of industry experience, strong technical strength, sufficient production capacity, reasonable price, good business reputation, products exported to many countries and regions. If you want to know more about the latest product information of Precision PU gasket dispensing machine, and want to find high-quality Precision PU gasket dispensing machine, please send an email to get the latest product quotation and contact.